Suction Centrifugal Pump Set With Vacuum Drinking Water Function

Suction Centrifugal Pump Set With Vacuum Drinking Water Function

Telephone:

0512-55176108

Landline:

0512-55176108

Mail:

0512-55176108

Address:

Room 3, No. 585 Guoshi Road, Kunshan Development Zone

Suction Centrifugal Pump Set With Vacuum Drinking Water Function

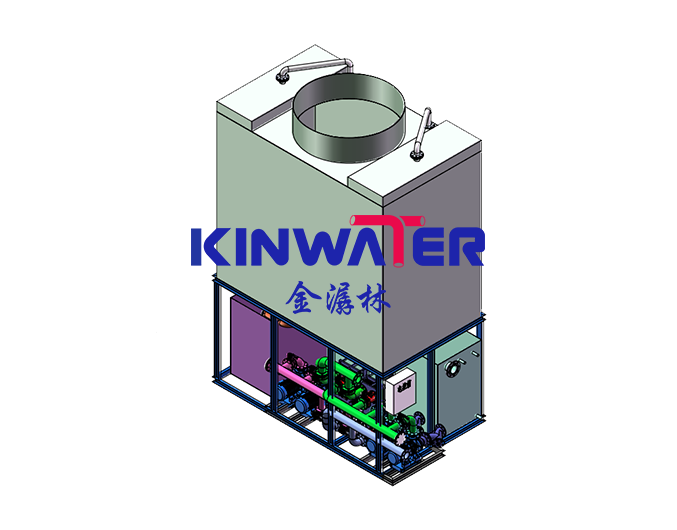

Fluid flow in the coil, the outer wall of the coil is sprayed with water package, the heat of the fluid through the pipe wall transfer, and water and air to form saturated warm steam, heat from the fan into the atmosphere, the water is blocked back to the water collection tank cycle spray, spray water in the cycle of the process of PVC heat sink to reduce the water temperature, and the formation of fresh wind and water flow in the same direction, the coil mainly relies on the sensible heat heat conduction mode.

Sheet metal open cooling tower combined with process plate heat exchanger in one unit to provide efficient cooling and heat exchange. The open design optimizes air flow and the sheet metal material is corrosion resistant. Plate heat exchanger enhances heat exchange efficiency, compact structure and easy maintenance. The overall system is energy efficient, low noise, and suitable for a variety of industrial applications.

Sheet metal open cooling tower is a kind of equipment used in industrial cooling system with open cooling structure, adopting corrosion-resistant sheet metal material and optimized heat sink design to ensure efficient cooling. Modular and easy to maintain, adapt to outdoor environment, equipped with noise reduction technology, support intelligent control, energy saving and high efficiency.

Sheet metal open cooling towers are widely used in industrial fields that require a large amount of cooling water, such as chemical industry, electric power, metallurgy and so on.

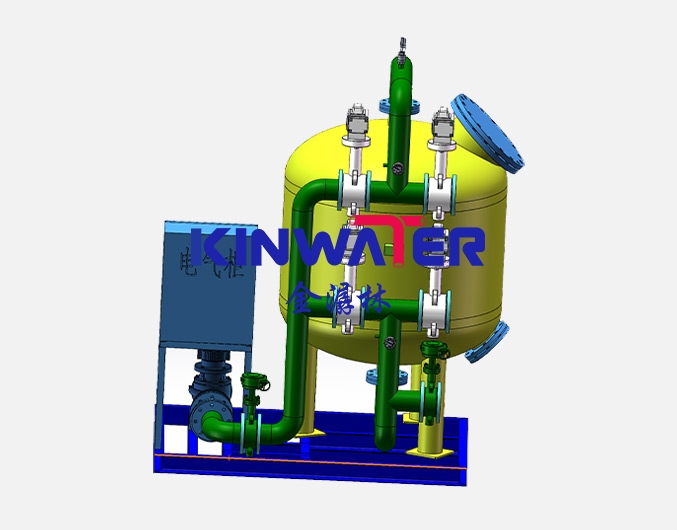

Quenching liquid filtration and cooling machine integrates filtration and cooling functions, specially designed for quenching process. The efficient filtration system removes impurities in the quenching liquid and keeps the liquid pure; the built-in cooling system rapidly reduces the liquid temperature and ensures the uniformity of heat treatment. Compact structure, easy to operate, improve production efficiency and extend the service life of quenching medium.

The quenching liquid filtering and cooling machine is suitable for metal heat treatment industry, such as machining, automobile manufacturing, aerospace, etc. It provides rapid cooling and impurity filtering of quenching liquid, ensures the uniformity of heat treatment, and improves product quality and production efficiency.

Sets of sand filter unit is a kind of equipment used for water treatment, which usually consists of several sand filters, and can remove suspended matter, sediment, microorganisms and other impurities in water. This equipment is widely used in industrial water, drinking water treatment and wastewater treatment. Sand filters filter through a sand layer, utilizing the pore structure of the sand layer to intercept particles in the water.

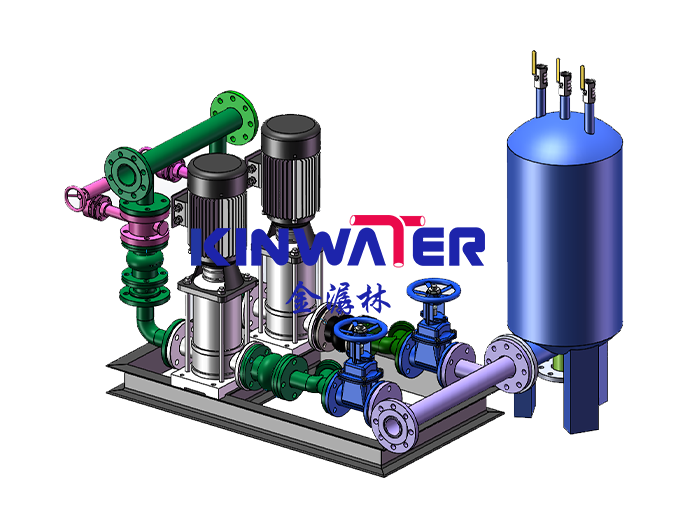

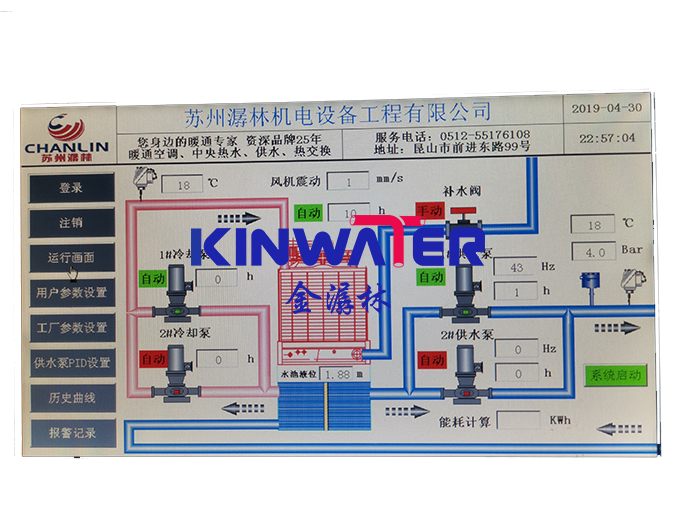

Water replenishment, softening and pressure setting integrated unit is a kind of integrated water treatment equipment, with automatic water replenishment, water softening and constant pressure water supply function. The unit softens water quality through ion exchange, reduces scale and improves thermal efficiency; the automatic water replenishment system keeps the system pressure stable and avoids the entry of air; the intelligent pressure setting function ensures constant water supply pressure, which is suitable for central air-conditioning, heating system and other occasions.

The water replenishment softening and pressure setting integrated unit is widely used in central air-conditioning system, heating system, industrial circulating water system, etc. It can provide stable water quality and constant pressure to ensure efficient operation of the system, reduce the maintenance cost and prolong the service life of the equipment.

Reverse osmosis water treatment equipment as a pure water filtration production of special equipment, has been widely used in water treatment, purification of urban tap water, the production of electric power, electronics, pharmaceutical, medical and food industries such as pure water and ultrapure water, water for injections and the preparation of edible pure water; desalination of seawater and brackish water: the production of potable water; space water, pure water, etc.; liquor manufacturing water; chemical process concentration, separation, purification and water preparation; boiler supply water desalination water softening; paper, electroplating, printing and dyeing and other industries and wastewater treatment. and water preparation; desalination and softening of boiler make-up water; water and wastewater treatment for paper making, electroplating, printing and dyeing industries.

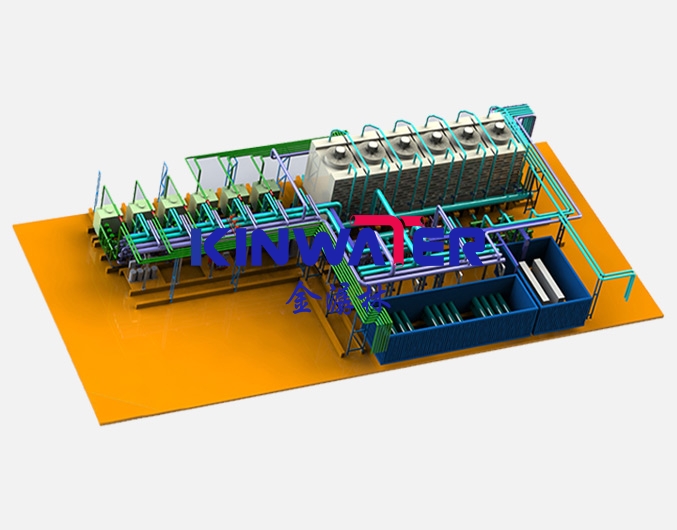

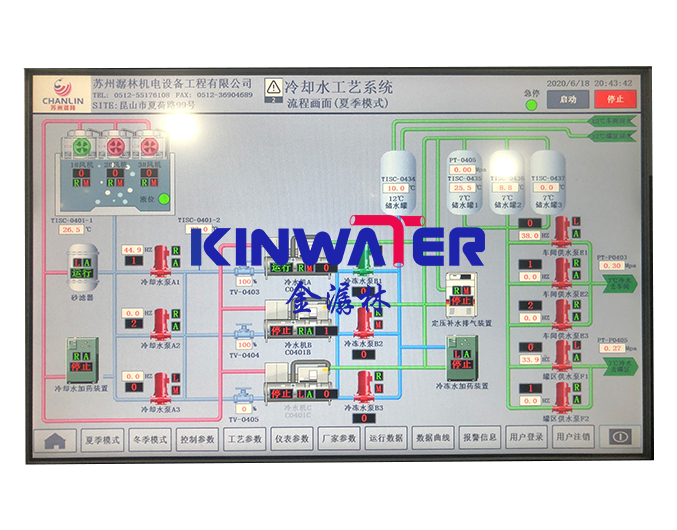

The Modular Multifunctional Energy Efficient Cooling System is a highly integrated cooling solution designed to meet commercial and industrial applications of varying sizes and demands. The system adopts a modular design, which makes it easy to expand or downsize for customized configurations according to specific needs. Components such as high-efficiency cooling towers, precision heat exchangers and intelligent pumping stations are integrated to ensure cooling efficiency and energy-saving performance. The system supports intelligent control and can automatically adjust operating parameters to optimize energy consumption and reduce operating costs. In addition, the modular design facilitates installation, maintenance and upgrading, improving system flexibility and reliability.

The High Quality Process Chilled Water and Production Line Heat Recovery System is an advanced industrial cooling and energy recovery solution. The system not only provides stable and efficient chilled water to meet the cooling needs of precision processes, but also reuses energy by converting waste heat generated in industrial processes into usable thermal energy through heat recovery technology. Designed for energy efficiency and environmental friendliness, the system is modularized for easy expansion and maintenance, and is suitable for industrial applications requiring large amounts of cooling and energy recovery.

The Cooling Storage Free Cooling System is a highly efficient, energy-saving cooling solution that utilizes the low-temperature environment at night to store cold and release it during the day to meet cooling demand. The system reduces reliance on traditional cooling equipment and lowers energy consumption through intelligent control and optimized operation modes. It is suitable for data centers, commercial buildings and other places that require continuous cooling. The system is designed to be flexible, and the cooling capacity can be adjusted according to actual demand to maximize cost-effectiveness.

Specialized sheet metal open cooling towers for cooling of toxic media emulsions are designed for special industrial applications with high corrosion resistance and safety. The use of special materials and sealing design ensures no leakage of toxic emulsions during the cooling process, protecting the environment and operators. The system has high efficiency heat exchange performance, through the large surface area of the heat sink to achieve rapid cooling. Intelligent control system monitors and regulates the cooling process to ensure stable operation. Suitable for chemical, pharmaceutical and other industries that need to handle hazardous media.

Contact us

+860512-55176108

Home

Home Products

Products Telephone

Telephone Message

Message